- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Language

Views: 222 Author: Ella Publish Time: 2025-04-17 Origin: Site

Content Menu

● Core Principles of Hydraulic Pump Motors

● Key Components and Their Functions

● Types of Hydraulic Pump Motors

● FAQs

>> 1. How is a hydraulic pump motor different from a regular electric motor?

>> 2. Can hydraulic pumps run in reverse?

>> 3. What determines a hydraulic motor's torque output?

>> 4. Why does my hydraulic system overheat?

>> 5. How do I select the right pump-motor pair?

Hydraulic pump motors are the backbone of modern industrial and mobile machinery, converting electrical or mechanical energy into precise hydraulic power. These systems rely on interconnected pumps and motors to transmit force through pressurized fluid, enabling heavy lifting, precise movements, and high-torque operations. This article explores their working principles, components, real-world applications, and troubleshooting tips, supported by diagrams, animations, and video explanations.

Hydraulic pump motors operate on the fundamental principle of energy conversion:

1. Mechanical to Hydraulic Energy:

- The pump (driven by an electric motor or engine) draws fluid from a reservoir and pressurizes it.

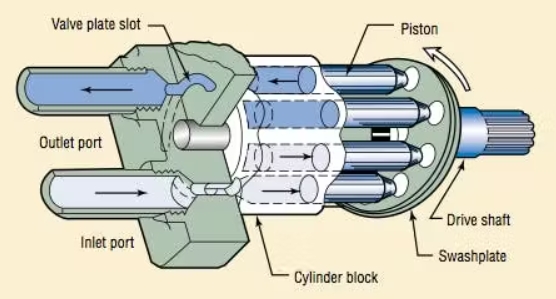

- Gear pumps use meshing gears to trap fluid, while piston pumps rely on reciprocating pistons.

- Example: A 20-hp electric motor driving a piston pump can generate up to 3,000 PSI in industrial presses.

2. Hydraulic to Mechanical Energy:

- The hydraulic motor converts fluid pressure back into rotational force.

- Torque output depends on displacement (e.g., 100 cc/rev motors generate higher torque than 50 cc/rev models).

Types:

- Gear Pumps: Affordable, fixed-displacement units for low-pressure systems (up to 2,500 PSI).

- Piston Pumps: High-efficiency, variable-displacement designs for pressures exceeding 6,000 PSI.

- Vane Pumps: Mid-range option (3,000–4,000 PSI) with balanced pressure for steady flow.

Critical Metrics:

- Flow rate (GPM) determines actuator speed.

- Pressure (PSI) defines force capacity.

Types:

- LSHT (Low-Speed High-Torque): Ideal for winches (1,500 RPM).

Efficiency Factors:

- Volumetric efficiency (90–95% in premium motors).

- Mechanical losses from bearing friction.

Case Study: A radial piston motor in a wind turbine yaw system delivers 12,000 Nm torque at 30 RPM.

- Accumulators: Store pressurized fluid for peak demand (e.g., crane boom retraction).

- Heat Exchangers: Maintain optimal oil temperature (140–180°F).

- Proportional Valves: Enable precise flow control in CNC machinery.

- Pump Example: External gear pump with 15 GPM flow.

- Motor Pairing: Gerotor motors for compact agricultural equipment.

- Advantage: Low maintenance in dirty environments.

- Pump Example: Variable-displacement axial piston pump with 45° swashplate.

- Motor Pairing: Bent-axis motors for construction excavators.

- Advantage: Pressure compensation adapts to load changes.

1. Excavators:

- Hydraulic pump motors power boom, arm, and bucket movements.

- Electro-hydraulic hybrids (e.g., Liebherr R 9200) reduce fuel use by 25%.

2. Drill Rigs:

- High-pressure piston pumps (5,000 PSI) drive rotary heads.

1. Injection Molding:

- Servo-driven pumps maintain ±1% pressure accuracy.

2. Robotic Arms:

- Compact vane motors enable 0.1mm repeatability in assembly lines.

1. Wave Energy Converters:

- Hydraulic pump motors stabilize power output from oscillating buoys.

2. Hydropower:

- Adjustable pumps store energy via pumped-storage systems.

- IoT Sensors: Monitor pressure, temperature, and contamination in real time.

- Predictive Maintenance: AI algorithms forecast pump wear using vibration data.

Example: Bosch Rexroth's Sytronix solutions cut energy costs by 70% in plastic extrusion.

1. Pressure Testing:

- Compare pump outlet pressure to specs using a calibrated gauge.

2. Flow Analysis:

- Measure actual vs. rated GPM with a flow meter.

3. Fluid Inspection:

- Check for ISO cleanliness code (target: 18/16/13).

1. Daily: Check fluid levels and inspect for leaks.

2. Monthly: Replace breather caps and test relief valves.

3. Annually: Flush reservoirs and rebuild pumps/motors.

Pro Tip: Use synthetic hydraulic fluids in extreme temperatures (-40°F to 250°F).

From skyscraper cranes to precision robotic arms, hydraulic pump motors deliver unmatched power density and control. Innovations like electro-hydraulic actuation and IoT integration are driving sustainability and efficiency across industries. By selecting appropriate components and adhering to maintenance schedules, operators can achieve decades of reliable service.

Hydraulic motors excel in high-torque, variable-speed applications, while electric motors struggle with overload conditions.

Reversing rotation damages shaft seals. Always confirm direction via the pump's arrow marking.

Torque (Nm) = (Displacement (cc/rev) × Pressure (bar)) / 20π.

Low viscosity fluid or undersized coolers often cause thermal runaway.

Match the motor's displacement to the pump's flow: RPM = (GPM × 231) / Displacement (in³/rev).

[1] https://www.panagonsystems.com/hydraulic-pumps-and-motors-in-action/

[2] https://www.youtube.com/watch?v=buXKmpRZZVc

[3] https://www.youtube.com/watch?v=K_ax7YcSZhA

[4] https://www.hydparts.com/blog/114/faqs-let-s-talk-about-hydraulic-pumps

[5] https://engineering.stackexchange.com/questions/481/motor-for-a-hydraulic-pump-in-a-hydraulic-system

[6] https://www.valmet.com/insights/articles/up-and-running/reliability/RTHPUTrouble/

[7] https://hydraulicpump-suppliers.com/blog/hydraulic-pump-and-motor/

[8] https://www.powermotiontech.com/hydraulics/hydraulic-pumps-motors/article/21884401/fundamentals-of-hydraulic-motors

[9] https://www.quadfluiddynamics.com/6-common-questions-you-may-have-about-hydraulic-pumps

[10] https://info.texasfinaldrive.com/shop-talk-blog/5-common-hydraulic-motor-questions-answered

[11] https://www.youtube.com/watch?v=swFeki_TfJc

[12] https://www.linkedin.com/pulse/common-faqs-hydraulic-pumps-hytorc-virginia-axtjc

[13] https://rotontek.com/how-does-a-hydraulic-pump-motor-work/

[14] https://www.machinerylubrication.com/Read/31064/troubleshooting-hydraulic-pumps

[15] https://www.powermotiontech.com/hydraulics/hydraulic-pumps-motors/article/21884136/engineering-essentials-fundamentals-of-hydraulic-pumps

[16] https://www.iqsdirectory.com/articles/hydraulic-pump.html

[17] https://en.wikipedia.org/wiki/Hydraulic_motor

[18] https://www.youtube.com/watch?v=5M42kdA5nyU

[19] https://www.youtube.com/watch?v=7rNjC75HWek

[20] https://peasleetech.org/wp-content/uploads/2020/01/Lecture-10HydPne.pdf

[21] https://testbook.com/mechanical-engineering/hydraulic-motors-definition-construction-and-types

[22] https://www.youtube.com/watch?v=luC8Ozcz6v0

[23] https://www.youtube.com/watch?v=7aZghp-iI3g

[24] https://www.youtube.com/watch?v=aOerEW7OR8o

[25] https://hosebox.com/insights/part-2-exploring-pumps-motors-powering-hydraulic-systems/

[26] https://www.youtube.com/watch?v=TBxMgGq3O94

[27] https://www.pumps.org/resources/pump-faqs/

[28] https://advancedfluidsystems.com/files/resources/Hydraulic%20System%20Troubleshooting%20Guide.pdf

[29] https://ie-g.com/faq-about-hydraulic-power-unit/

[30] https://www.reddit.com/r/Hydraulics/comments/1f3g16l/questions_about_hydraulic_motors/

[31] https://www.whitehouseproductsltd.com/blog/hydraulic-pump-troubleshooting-tips

[32] https://www.pumpsandsystems.com/hydraulic-pump-faqs-april-2011

[33] https://www.physicsforums.com/threads/basic-question-about-hydraulic-pumps.566667/

[34] https://supremeintegratedtechnology.com/blog/hydraulic-pump-problems

[35] https://www.cylinderservices.net/faqs/

[36] https://bbs.homeshopmachinist.net/forum/general/54050-hydraulic-motor-pump-questions

[37] https://www.mygrandrv.com/threads/intermittent-hydraulic-pump-motor-problem-and-solution.57040/

[38] https://www.harvardfiltration.com/understanding-need-of-hydraulic-pump/

[39] https://www.youtube.com/watch?v=pWuxYnqYDnk